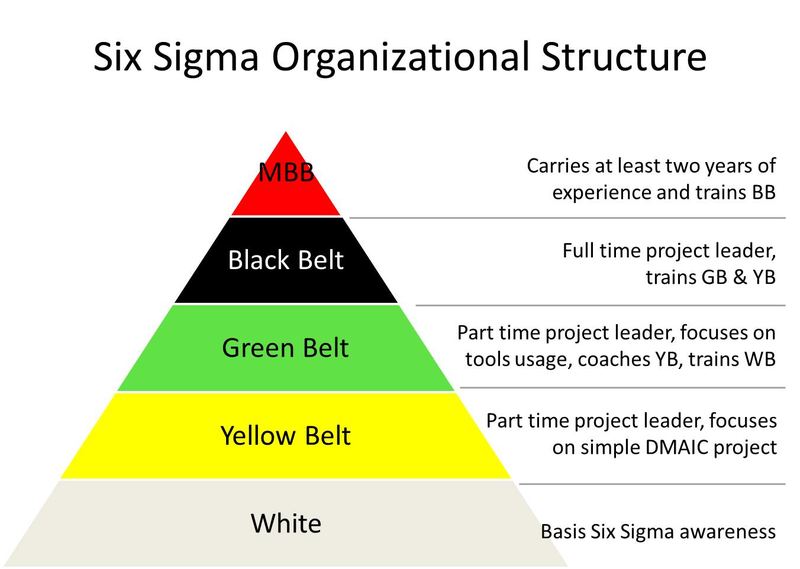

Non-Used Talent: Non-Used Talent refers to the waste of human potential and skill.Examples include waiting for authorization from a superior, waiting for an email response, waiting for material delivery, and slow or faulty equipment. Waiting: Waiting involves delays in process steps and is split into two different categories: waiting for material and equipment and idle equipment.Examples include creating unnecessary reports and overproduction of a product before a customer has requested it. Over-production: Over-production refers products made in excess or before it is needed.Examples include a product that is scratched during the production process and incorrect assembly of a product due to unclear instructions. Defects: A defect is a product that is declared unfit for use, which requires the product to be either scrapped or reworked, costing the company time and money.ĭifferent types of waste have been defined in the form of a mnemonic of "downtime": Waste ( muda) is defined by Fujio Cho as "anything other than the minimum amount of equipment, materials, parts, space, and workers time, which are absolutely essential to add value to the product". Lean Six Sigma organization structure Waste In order to achieve any of the certification levels, a proctored exam must be passed that asks questions about Lean Six Sigma and its applications. The skill sets reflect elements from Six Sigma, Lean and other process improvement methods like the theory of constraints and total productive maintenance. For each of these belts, level skill sets that describe which of the overall Lean Six Sigma tools are expected to be part at a certain belt level are available. Below the black belt are the green and yellow belts. The highest level of certification is a black belt, signifying a deep knowledge of Lean Six Sigma principles. The different levels of certifications are divided into belt colors. The five phases used in Lean Six Sigma aim to identify the root cause of inefficiencies and work with any process, product, or service that has a large amount of data or measurable characteristics available. Lean Six Sigma uses the Define, Measure, Analyze, Improve and Control ( DMAIC) phases similar to that of Six Sigma. Lean traditionally focuses on eliminating the eight kinds of waste (" muda"), and Six Sigma focuses on improving process output quality by identifying and removing the causes of defects (errors) and minimizing variability in (manufacturing and business) processes. Lean Six Sigma is a synergized managerial concept of Lean and Six Sigma. In the early 2000s Six Sigma principles expanded into other sectors of the economy, such as healthcare, finance, and supply chains.

#6 sigma belt levels how to#

It was developed as a guide for managers of manufacturing plants on how to combine lean manufacturing and Six Sigma to improve quality and cycle time in the plant. The first concept of Lean Six Sigma was created in Chuck Mills, Barbara Wheat, and Mike Carnell's 2001 book, Leaning into Six Sigma: The Path to Integration of Lean Enterprise and Six Sigma.

While Lean Six Sigma developed as a specific process of Six Sigma, it also incorporates ideas from lean manufacturing, which was developed as a part of the Toyota Production System in the 1950s. A few years later, General Electric's Jack Welch consulted Bossidy and implemented Six Sigma at the conglomerate.ĭuring the 2000s, Lean Six Sigma forked from Six Sigma and became its own unique process.

In the 1990s, Allied Signal hired Larry Bossidy and introduced Six Sigma in heavy manufacturing. Six Sigma was developed within Motorola to compete with the kaizen (or lean manufacturing) business model in Japan. Lean Six Sigma's predecessor, Six Sigma, originated from the Motorola company in the United States in 1986. It combines Lean Management and Six Sigma to increase the velocity of value creation in business processes. Lean Six Sigma is a process improvement approach that uses a collaborative team effort to improve performance by systematically removing operational waste and reducing process variation. JSTOR ( December 2021) ( Learn how and when to remove this template message).Unsourced material may be challenged and removed. Please help improve this article by adding citations to reliable sources. This article needs additional citations for verification.

0 kommentar(er)

0 kommentar(er)